The new federal government procurement regulations effective in October, 2022 will demand for Local Manufacturing and higher domestic content. However, after two decades of offshoring productions to low-cost countries, many American companies might have lost touch with manufacturing – the Association of Manufacturing Technology estimated a “technical debt” of up to $600 billion in the U.S. manufacturing sector. How to turn offshoring to Local Manufacturing quickly to qualify for the new regulations? This blog explains how Microfactory helps manufacturers localize production!

Federal Procurement Regulations

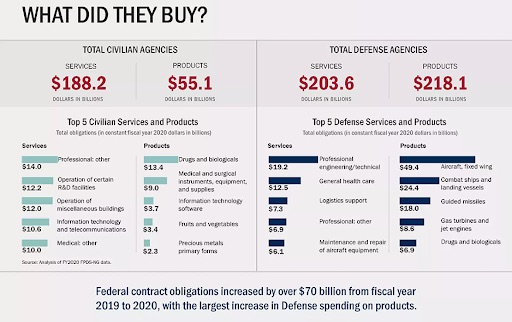

Federal government procurement is a vast market space. In 2020, the federal government spent more than $665 billion on contracts, increasing by over $70 billion from 2019. That is why domestic content is a big deal for U.S. companies – by qualifying for the required domesticity rate, they can ensure eligibility for federal procurements, opening significant, profitable, multi-year revenue streams.

The Federal Acquisition Regulatory (FAR) Council published new rules that increase domestic content requirements for federal government procurements and enhance price preferences for domestic goods designated as critical to U.S. supply chains. The rule was aimed at maximizing the use of domestic products, materials, and services and improving supply chain resiliency in critical sectors, such as information and communications technology, clean energy, defense, public health, agriculture, and transportation.

Federal procurements in 2020 (Source: U.S. Government Accountability Office)

New Domestic Content Rule

Domestic content determines whether solicited construction material or end products are domestic. Currently, the FAR uses a two-part test to assess domesticity for the Buy American Act (BAA). Firstly, the end products must be manufactured locally in the United States. Secondly, a certain percentage of the cost of the components used in the end products must be of U.S. origin, whether they were mined, produced, or manufactured in the country. Currently, the rate of domestic compliance is 55 percent. Effective October 25, the threshold will increase to 60 percent, followed by an increase to 65 percent in 2024 and to 75 percent in 2029.

Enhanced Price Preference

Should there be a federal procurement case with a domestic alternative more expensive than a foreign offer, the procuring agency can apply the so-called price preference – that is, add a predefined percentage on top of the price of the foreign offer to favor the domestic alternative (the domestic price must not exceed the foreign price by more than the price preference). Under the current FAR, price preference is 20 percent for large businesses, 30 percent for small businesses, and 50 percent in the defense sector.

Challenge in the U.S. Manufacturing

After two decades of offshoring productions to low-cost countries, many U.S. companies have lost touch with manufacturing. The Association of Manufacturing Technology estimated that the United States must invest $400-600 billion in manufacturing technologies to become competitive and balance its trade deficit with importers such as China. This technical debt is partly a result of the great offshoring boom; manufacturing skills and technologies were not needed locally during this epoch, creating a vacuum in the U.S.

Now U.S. companies are facing a tough localization challenge. To succeed in the $665 billion federal procurement market, they must rapidly increase skilled labor and advanced technologies investment, ramp up Local Manufacturing, and localize sourcing raw materials and components to meet the new domestic content regulations.

The Solution is Local Manufacturing!

The location of manufacturing is the single most significant factor in the equation of domestic content. Offshoring manufacturing outside of the United States reduces domesticity radically; actually, it can be prohibitive for the company to qualify for federal government procurements. In an offshoring scenario, materials and components are typically sourced near the foreign production plant because it makes economic sense. However, the combination of offshoring and foreign sourcing negatively impacts domestic content and, in the worst case, disqualifies the company for federal procurement.

On the other hand, Local Manufacturing gives a company’s domestic content a positive boost. Local Manufacturing allows companies to centralize sourcing locally in the United States at the federal level. Manufacturing and production can be localized in a selected state using the agile Microfactory concept.

Benefits of Local Manufacturing

Local Manufacturing allows companies and manufacturers to capitalize on state subsidies, employ locally, establish a healthy give-and-take relationship with the community, and increase wellbeing. By optimizing supply chains with Local Manufacturing, manufacturers can reduce the delivery time by several weeks compared to offshoring. Local Manufacturing saves money via the lower working capital and increased resiliency against supply-chain disruptions. Also, logistics costs are decreased, lead times are shortened, forecasting becomes more accurate, and inventory and waste are reduced. Companies can increase quality when all operations are handled locally together with sub-contractors. Local Manufacturing can entitle U.S. companies to claim price preference in federal government procurements, stick a Made in the USA label on the box, and enjoy a substantial price premium!

Why Use Microfactory for Local Manufacturing?

A microfactory concept is a modular, automated assembly platform. Each module typically contains one application, and they are integrated through standard, pre-tested, and verified interfaces end-to-end. This enables manufacturers to customize and implement the line configuration and capacity flexibly according to their needs – yet the microfactory delivery time can be up to 30% faster than a traditional automation system. And, the onsite installation time can be even up to 90% faster – in fact, a microfactory can be installed in one day.

Modularity brings scalability. Start with a small assembly line and add more modules to increase capacity when the demand grows. That makes a Microfactory a perfect solution for Local Manufacturing, minimizing the initial investment costs and risks.

Microfactories require only limited floor space and operational staff compared to traditional factories, reducing operational costs and energy consumption. EID Robotics provides manufacturers with a full partnership, in-depth automation technology know-how, and 24/7 support!

Contact us here and let’s talk about Automation, Microfactories, and Local Manufacturing!