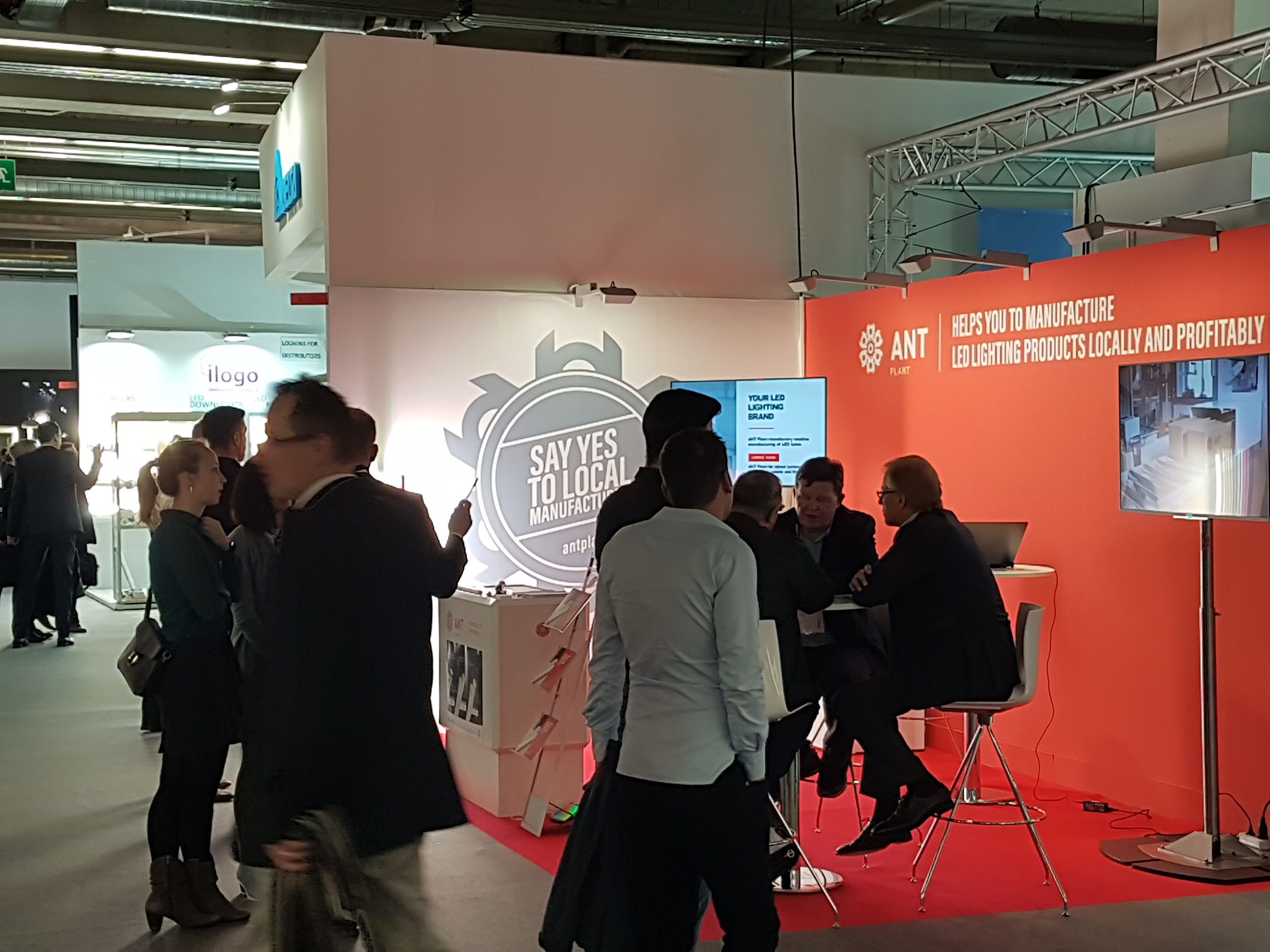

In March, we participated in the Light + Building 2018 exhibition where we talked to hundreds of international lightning experts. A poll we did at the exhibition revealed that, depending on the region and country, 83 per cent of all LED lighting products are manufactured in China, on average. In some countries, almost all LED lighting products on the market are imported from China.

However, importing LED lighting products from cheap labor countries is in many ways problematic and causes trouble for retailers. The orders transported from China take a long time to reach their destination, meaning the seller can’t react to changes in demand flexibly.

The LED lighting products in the containers of ocean liners tie up capital for weeks, or sometimes even months. The risks related to the delivery chain and logistics grow when products are manufactured far from the end users. The products are often lacking in quality, as well.

The labor costs in cheap labor countries, such as China, have increased year by year.

Technological progress enables us to return the manufacturing closer to our clients in a profitable way.

I also discussed this with Chinese guests at the exhibition, and I’d estimate that they are also interested in moving their own factories to Europe and the United States to be closer to the clients.

How should you go about reshoring the manufacturing of LED lighting products?

Our ANT Plant manufacturing concept is an easy solution for returning the manufacturing of LED lighting products close to the clients. Here’s what you should remember when considering an investment in a microfactory:

1) Make a realistic cost calculation and compare alternatives

“Well planned is half done” – this also applies to beginning the manufacturing of LED lighting products. It’s important to make a realistic calculation of how much importing the products costs the retailer, all expenses included. The calculation must include indirect costs, such as funding, logistics, complaints, customs duties, taxes and insurance costs. When you total up all costs, you can realistically compare them to the potential alternative: the ANT Plant manufacturing concept that enables you to manufacture LED lighting products locally and profitably.

2) Conduct a market survey and ensure you have the market for your LED lighting products

Next, you should make a detailed market survey. According to our research, people are ready to pay 10–20 per cent more for local, high-quality and well-branded products. In addition, the market potential of these products is better.

3) Learn about subsidies for local production

In many countries, the local government offers subsidies to investments aiming for local production because the production provides employment and tax income. You should find out which subsidies are available as early as possible.

4) Calculate the repayment period and make the decision

When the cost calculation and market survey show that the microfactory investment will pay itself back in less than a year, the investment can be considered risk-free. In the lighting business, consumers’ requirements change rapidly. The service agreement of the ANT Plant ensures that you won’t be left alone with the microfactory. The ANT Plant manufacturing concept is a partnership. The functions of the microfactory can be adjusted according to the changing needs, and the hubs of the ANT Plant manufacturing concept will ensure that the end-product materials are delivered to the microfactory on time.

5) Recruit employees to look after the microfactory and we’ll take care of the rest

The automatic ANT Plant only needs minimal staff. That’s because the LED tubes produced at an ANT Plant are automatically assembled, tested, labeled, and packaged. Your staff can focus on marketing and selling your LED lighting product and managing your company. The ANT Plant Service Center takes care of orienting employees, remotely updates and optimizes production, offers online support, and, when necessary, provides on-site support.

In summary, if you have a sufficiently broad market for the end product, investing in an automatic ANT Plant Microfactory is worth it.

Paavo Käkelä

VP Sales

+358 50 361 3945

paavo.kakela@eidrobotics.com