I was driving my car one day and listening to a chat show on the radio: two Finnish politicians were discussing how to pump more productivity into Finland’s economy. One interesting but incoherent suggestion was to impose “robot taxes” on companies that use automation to replace human workers in manufacturing.

The one part of the idea was that companies using robots would lose their cost advantage, so that robots can’t take all the jobs away from people. The most famous spokesperson for such a tax on robots is Bill Gates, who stated that the funds from it should go toward training those who have lost their job because of robotics.

Interesting views, but robot taxes are a minefield, and we need to be careful. If automation creates an opportunity to compete locally against imports from countries with lower labor costs, why destroy that advantage right away by sacrificing it to the tax man?

I’m not against the taxes. We need them to keep our societies running. Just need to be careful when planning new taxes. Besides, mass production has been offshored or sent overseas to “low-cost countries” since the early 1990s or before.

How can robots take our manufacturing jobs if those jobs aren’t in our country?

For example, nowadays LED tubes of Western brands are made mainly in cheap-production countries.

I think that, rather than pile on the taxes, we need to support new investments, to draw manufacturing closer to the end users. An additional tax for robotics doesn’t help very much with our efforts to prioritize local manufacturing and support companies’ efforts to nearshore. This is what President Trump is doing in his country: he is reducing taxes on companies, in attempts to bring manufacturing back to the USA.

Success in this isn’t about building huge factories. It’s a matter of creating flexible and well‑modularized, fully automated, intelligent microfactories that can serve the surrounding region.

Fully automated production with the latest robot technology still improves local well-being throughout the region.

Even if operations are 100% automated, they always provide people with work – for instance, to support the manufacturing and handle human–robot collaboration.

While a fully automated and intelligent microfactory doesn’t need people to assemble or package the products, someone still has to do other specialist work.

As ManpowerGroup puts it, this is a matter of transforming jobs, not eliminating them. The company’s chairman and CEO, Jonas Prising, says, “Digitalization is transforming the job market, creating a need for people withmore advanced skills in manufacturing.” Technological advances in tools for engineering already make it necessary to have a college degree in many types of manufacturing jobs. This development brings new possibilities for millions of workers with skills inadvanced machinery in the near future.

This doesn’t mean that you need to be a manufacturing specialist to run the factory, though. All you need is a market for the end product – the rest you can arrange to receive as a service.

The surprising result is that at the end of the day you have a high‑quality yet cost-competitive product in your hand that truly was produced locally. No shipping costs, no human error, and no possibility of poor work conditions in the factory as can often be found in low-labor-cost countries.

For some years now, we at EID Tech have been looking into how local manufacturing can be cost‑competitive and have a lower total cost of ownership (TCO) than overseas manufacture of items such as LED lighting products.

The main conclusion from our research is that all of us need to increase the level of automation in our manufacturing.

The same conclusion was reached by Cambridge University’s Senior Lecturer in Public Policy Finbarr Livesey, as outlined in his book From Global to Local: The Making of Things and the End of Globalisation and the article “Manufacturing Is Staying Home: How GE and Adidas AreSetting the Standard in Higher-cost Economies”. He thinks that we are going to see the end of globalization. Deglobalization is already taking place.

Also, the Boston Consulting Group has conducted research into a fourth manufacturing revolution or Industry 4.0. They say that the manufacturing revolution to be happening right now, with robotics and other new technologies (such as 3D printing) boosting productivity, growth, and employment. We just need to get ready and train our people to work in more advanced jobs.

So, with the aid of robotics, we can take up nearshoring or bring production all the way back home if it isn’t already close to the users, supporting the local economy. Automation is the answer, and at EID Tech we have spent many years preparing for the upcoming manufacturing revolution.

We are ready to offer a practical local-manufacturing-based alternative to imports of cheap merchandise from low-labor-cost countries.

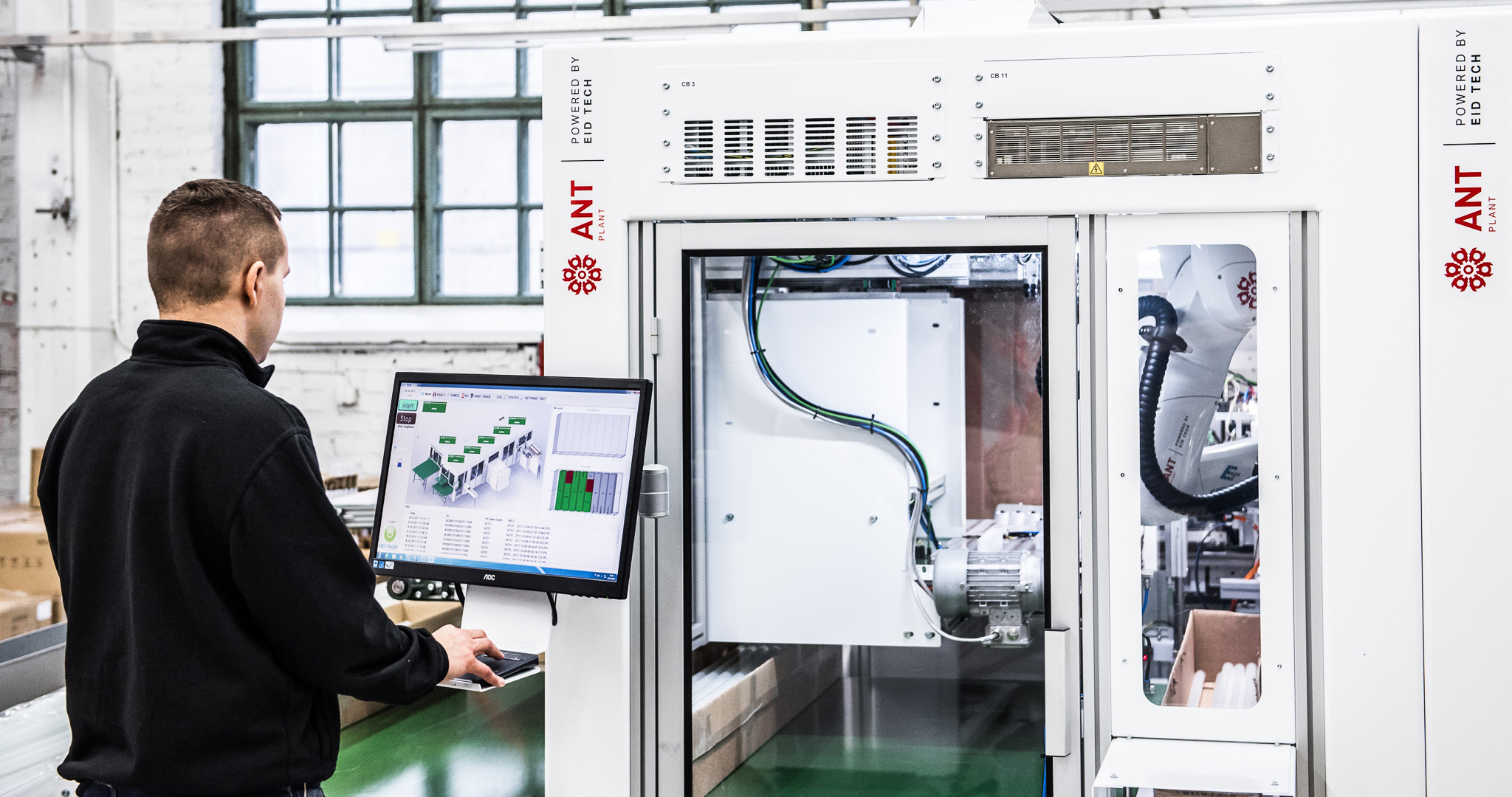

EID Tech’s ANT Plant microfactory for LED lighting has been developed to help you find the best and most energy-efficient, productive, and TCO-friendly solution for you, precisely matching your needs.

In my view, it is a task for all of us to continue our work toward making the world a better place to live. And we aren’t doing this only for ourselves. We are doing this for the sake of our children and grandchildren as well.

“EID” stands for “Everything is Doable,” and by being true to our slogan, “EID Together”, we believe we really can change the world together, with you!

Paavo Käkelä

VP Sales

+358 50 361 3945

paavo.kakela@eidrobotics.com